Strong Infrastructure, Better Solutions for You

At Trellis, our strong infrastructure is the pillar of our commitment to delivering the best to our customers every day. Our state-of-the-art R&D facility and factory are equipped with advanced testing and packaging systems, ensuring top-notch quality at every step.

We go above and beyond to satisfy all of our customers’ needs rather than merely meeting them. Every material undergoes careful testing at our factory and laboratory, guaranteeing optimal performance and reliability before it reaches you. Because for us, quality isn’t a checkpoint—it’s a promise.

Research and Development

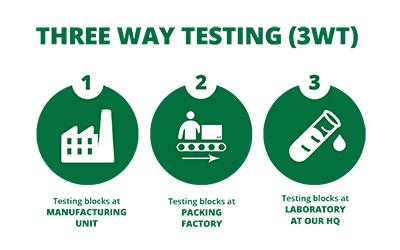

Triple-Checked for Unmatched Quality – Our Three-Stage Testing Method

Quality you can trust, tested at every step. Our unique 3ST – Three Stage Testing process guarantees triple confirmation on critical parameters like expansion and EC, ensuring only the best reaches you.

Here’s how:

Stage 1: Testing at our manufacturing unit to ensure consistency from the start.

Stage 2: Rechecking at our packing facility for added care.

Stage 3: Final validation at our headquarters laboratory for absolute reliability.

When it comes to quality, we believe in testing, testing, and testing again. Every product. Every time.

Our Factory

Perfection at Every Step – Our In-House Testing Facility

Our in-house laboratory is the heart of our quality assurance, ensuring every product meets the highest standards of quality and quantity before reaching our customers.

Through in-depth research and analysis, our experts have gained valuable insights into the unique needs of different plants. This knowledge has driven the development of application-centric products, designed to provide customised solutions for every plant’s specific requirements.

We don’t just grow products—we grow solutions.

Reliable In-House Packaging & Labelling

At Trellis, we focus on delivering the best products with the right packaging. Our fully automated system ensures consistent packaging, reducing errors and maintaining quality.

With in-house machinery, we can closely monitor size, weight, and specifications, ensuring every package meets our customers’ exact requirements. This gives us better control, helping us deliver as promised, every time.

Efficient & Organized – Our 5S Certified Infrastructure

At Trellis Horticulture, we believe in working smarter. Our 5S Certified infrastructure ensures that our warehouses and offices stay organized, efficient, and clutter-free.

By following the 5S Lean Management Technique, we streamline our inventory, remove unnecessary steps, and create a structured workflow. The result? Better productivity, faster processes, and a more efficient way of working—every single day.